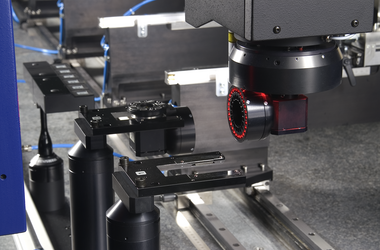

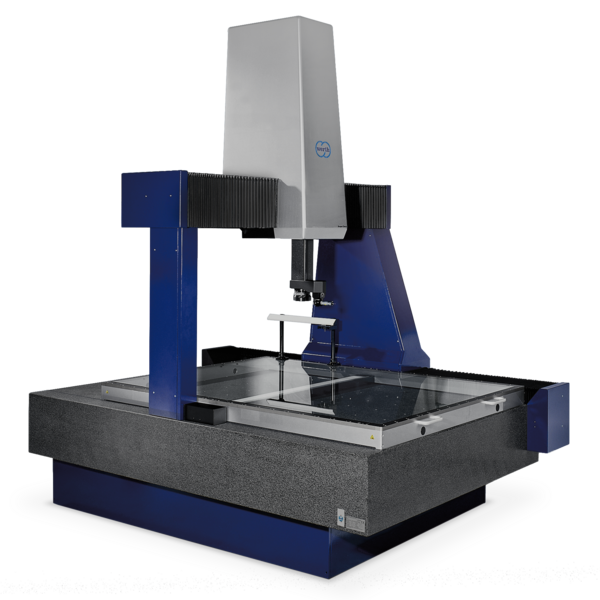

A bone screw usually has several types of threads in the head area, so that special requirements are placed on the drive. Bone screws can be self-tapping. The most important parameters are the mould of the drive, taper, pitch and the geometry of the key surfaces. Due to the tolerances of approx. 10 µm to 20 µm, the requirements for measurement uncertainty are high. The demands on the measuring time are very high, as a 100% check is usually carried out. Due to the thread pitch, a 5-axis system is recommended as the measuring machine.

-

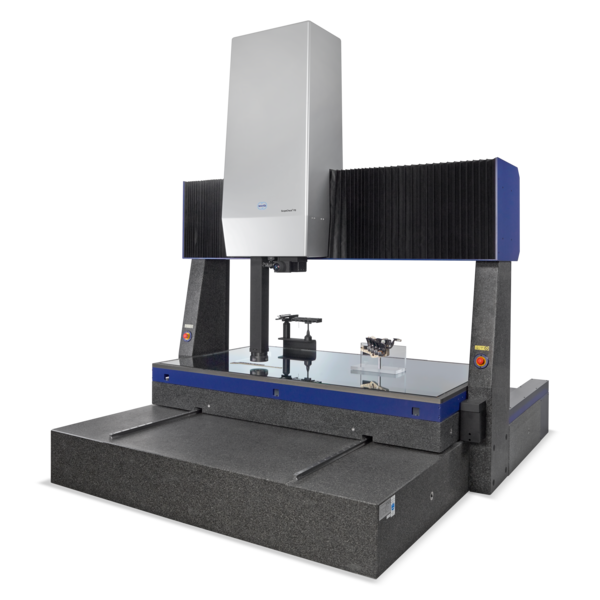

Applications

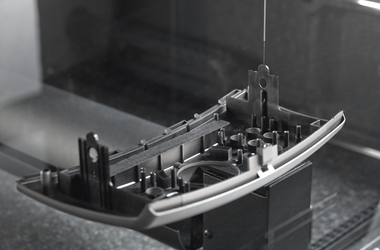

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Stamped and bent parts

- Packaging

- Shaft-hub connections

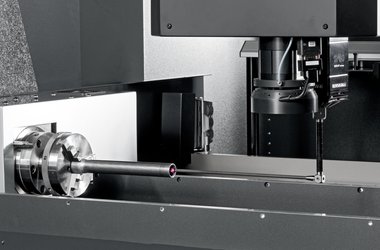

- Shafts and axles

- Workpieces with micro-features

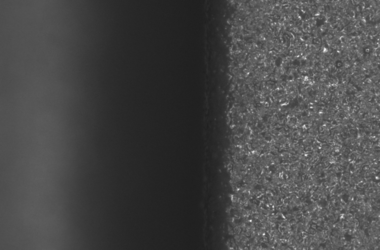

- Workpieces with optical functional surfaces

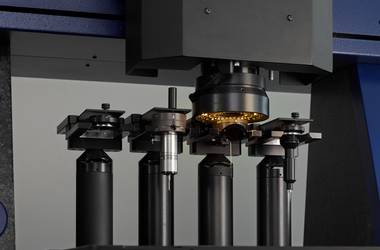

- Tools with geometrically defined cutting edges

- Tools with geometrically undefined cutting edges

- Gears

- Cylindrical workpieces

- Industries

- Products

- Service

- About Werth

- Careers

- Foundation

- Publications

- Downloads