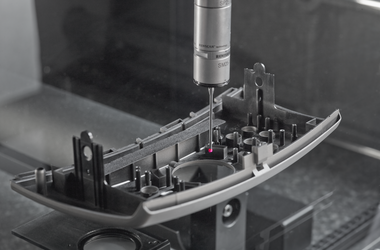

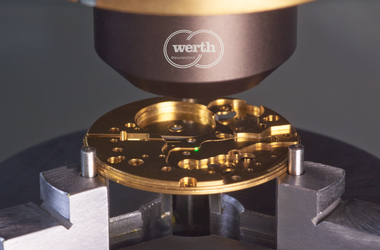

Grinding wheels consist of geometrically undefined cutting edges and a polycrystalline surface. In addition to the profile, angles, radii and distances are measured, directly on the grinding wheel or on the grinding-in coupon.

Other parameters are grain size, grain protrusion and contact ratio of the ground surface. With tolerances of approx. 20 µm and mostly in-process measurements, the requirements for measurement uncertainty and measurement time are high. The surface is partly highly reflective, partly transparent and places special demands on the sensors.

-

Applications

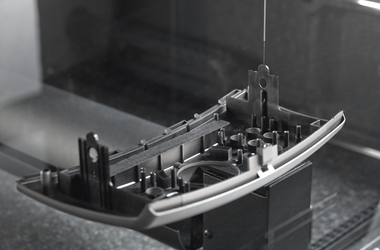

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Stamped and bent parts

- Packaging

- Shaft-hub connections

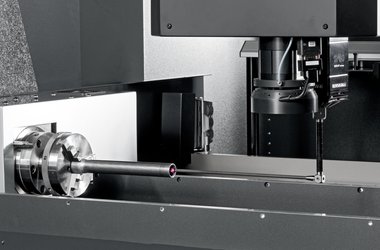

- Shafts and axles

- Workpieces with micro-features

- Workpieces with optical functional surfaces

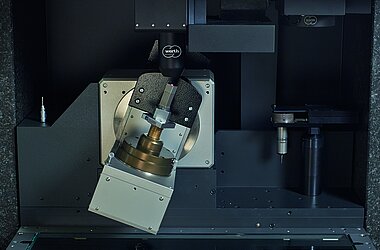

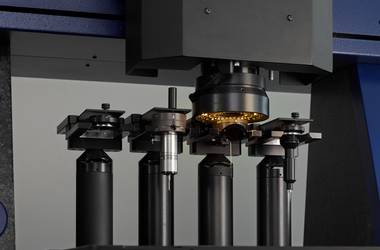

- Tools with geometrically defined cutting edges

- Tools with geometrically undefined cutting edges

- Gears

- Cylindrical workpieces

- Industries

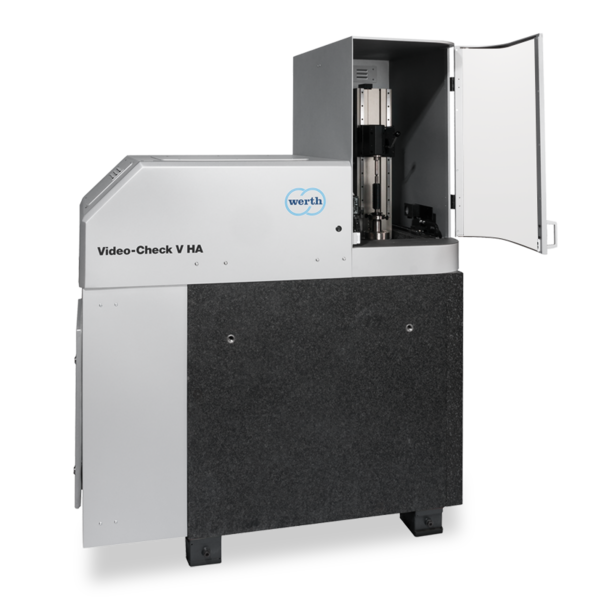

- Products

- Service

- About Werth

- Careers

- Foundation

- Publications

- Downloads