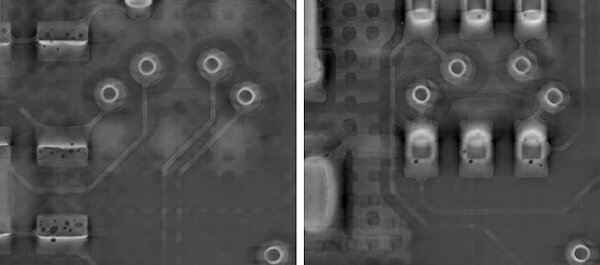

To achieve high resolution, the distance between the workpiece and the X-Ray tube must be very small. If large, flat workpieces such as printed circuit boards are to be tomographed, the large aspect ratio would then cause the workpiece to collide with the X-ray source when it is rotated to acquire the radiographic images. A solution is offered by swing and planar laminography, in which the angular range for capturing the radiographic images is greatly reduced or movement takes place only in a planar manner.

For swing laminography, the workpiece is rotated only within a certain angular range, e.g., ±20 degrees. For planar laminography, the workpiece is moved through the X-ray beam while the detector and X-ray tube move in opposite directions. Due to the conical shape of the X-rays, the angle of transmission changes in the process. This virtual rotation of the workpiece provides sufficient information to reconstruct the volume of the workpiece. The lateral resolution in the different measuring planes is very high, defined by the selected magnification. The axial resolution is lower, which is usually not a problem in 2D applications.

Laminography is used, for example, for the analysis and measurement of printed circuit boards and electronic assemblies, the analysis of archaeological samples, 2D measurements of large metal sheets or flat plastic parts, and the measurement of bipolar plates.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Stamped and bent parts

- Packaging

- Shaft-hub connections

- Shafts and axles

- Workpieces with micro-features

- Workpieces with optical functional surfaces

- Tools with geometrically defined cutting edges

- Tools with geometrically undefined cutting edges

- Gears

- Cylindrical workpieces

- Industries

- Products

- Service

- About Werth

- Careers

- Foundation

- Publications

- Downloads