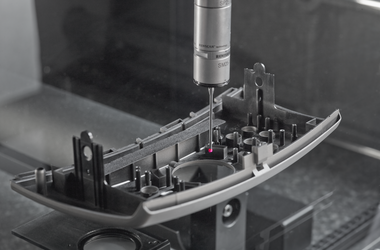

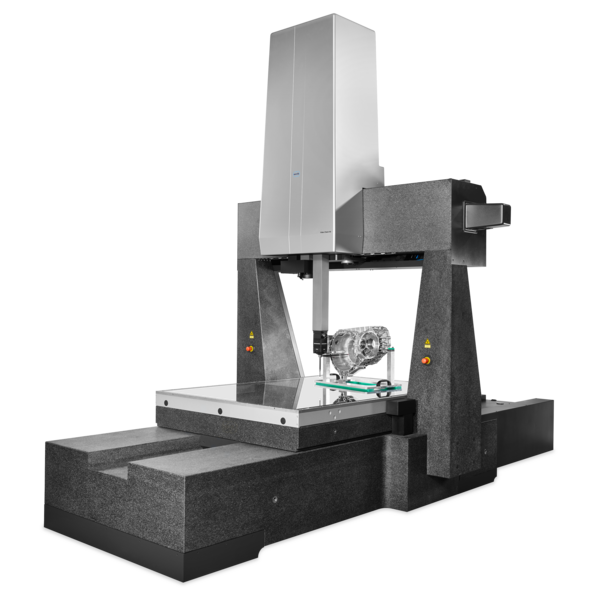

Similar to injection molds, die casting tools are corrected iteratively until the workpieces produced with them are safely in tolerance. In addition to distances, radii and angles, positional deviations and often the entire surface form deviation must be measured. With tolerances in the range of 5 µm to 10 µm, the requirements for measurement uncertainty are very high. The measuring time plays a subordinate role.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Stamped and bent parts

- Packaging

- Shaft-hub connections

- Shafts and axles

- Workpieces with micro-features

- Workpieces with optical functional surfaces

- Tools with geometrically defined cutting edges

- Tools with geometrically undefined cutting edges

- Gears

- Cylindrical workpieces

- Industries

- Products

- Service

- About Werth

- Careers

- Foundation

- Publications

- Downloads