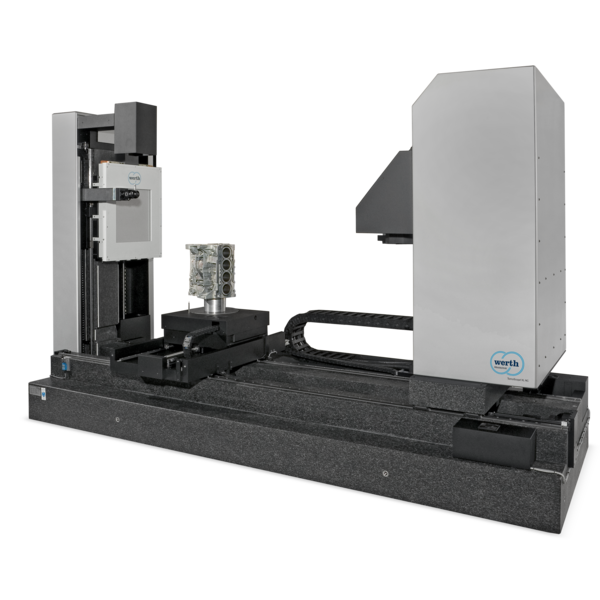

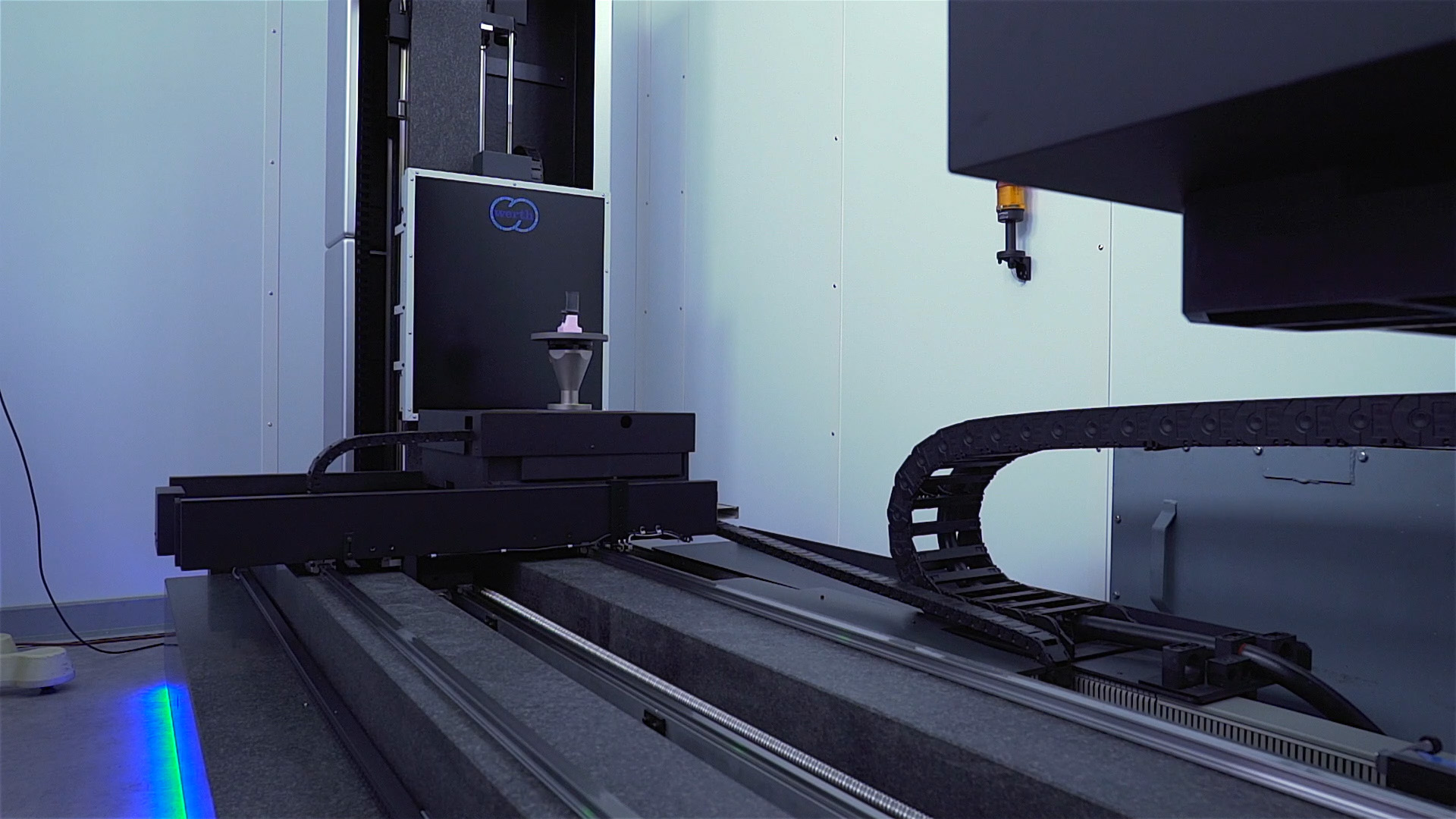

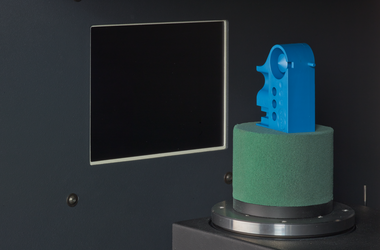

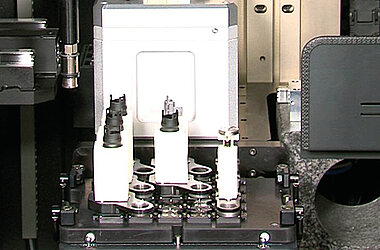

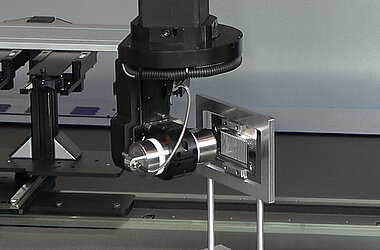

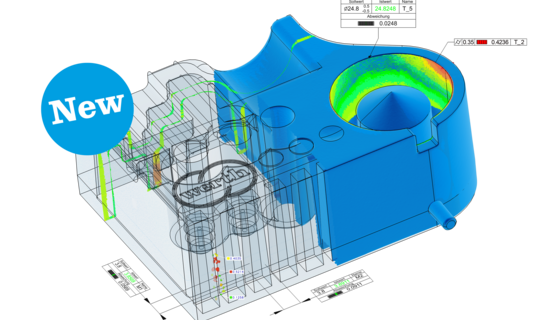

Due to a tube voltage of 450 kV, the TomoScope® XL NC is also suitable for measurement and inspection tasks on massive, large workpieces. To extend the range of applications, a second X-ray source can be used in automatic changeover in this multi-sensor coordinate measuring machine with X-ray tomography (CT), for example, to additionally measure small components with the highest resolution. Areas of application include 3D measurements of castings (engine blocks, cylinder heads) and ceramic workpieces.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Stamped and bent parts

- Packaging

- Shaft-hub connections

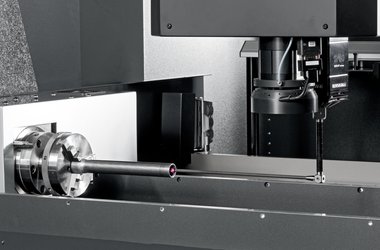

- Shafts and axles

- Workpieces with micro-features

- Workpieces with optical functional surfaces

- Tools with geometrically defined cutting edges

- Tools with geometrically undefined cutting edges

- Gears

- Cylindrical workpieces

- Industries

- Products

- Service

- About Werth

- Careers

- Foundation

- Publications

- Downloads