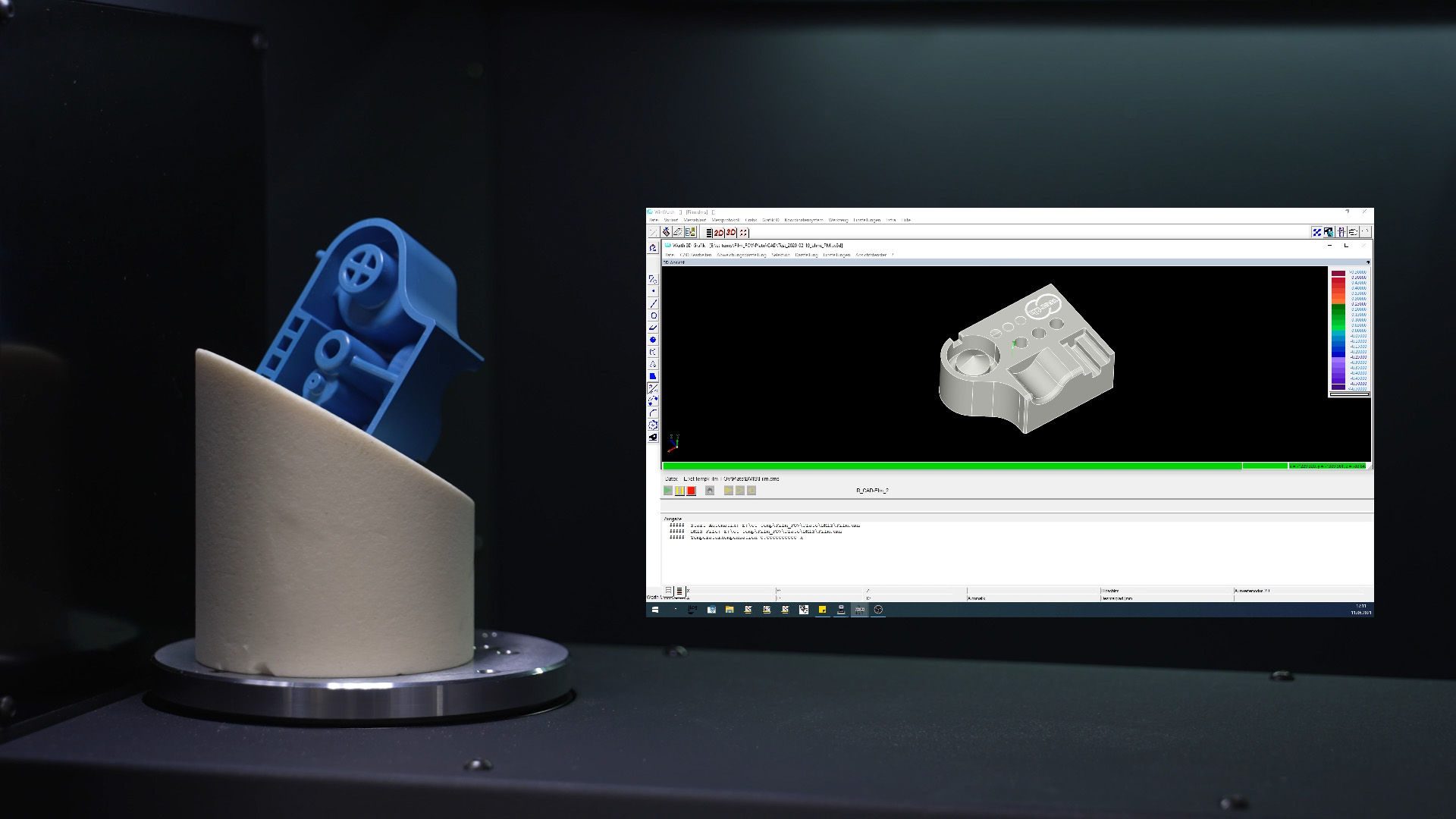

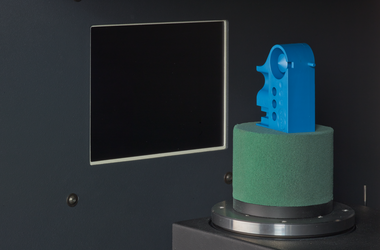

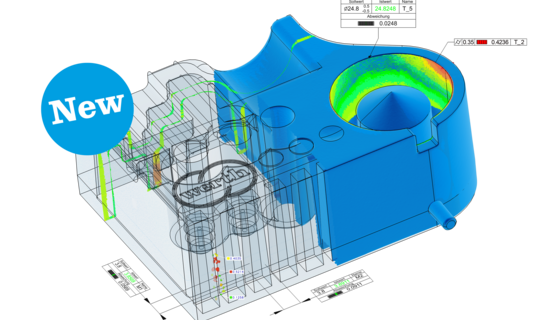

The TomoScope® XS FOV is a flexible and easy-to-use machine for fast measurements with industrial computed tomography. The 3D measurements take place in the detector's field of view without moving axes and can be fully automated. A high-performance X-ray tube optimises the measuring time, especially when using beam hardening filters. Several small workpieces such as lids or dowels can be measured together using suitable fixtures. The measurement of small metal parts such as dental implants, light metal workpieces or door hinges is also possible.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Stamped and bent parts

- Packaging

- Shaft-hub connections

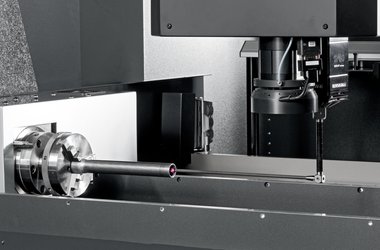

- Shafts and axles

- Workpieces with micro-features

- Workpieces with optical functional surfaces

- Tools with geometrically defined cutting edges

- Tools with geometrically undefined cutting edges

- Gears

- Cylindrical workpieces

- Industries

- Products

- Service

- About Werth

- Careers

- Foundation

- Publications

- Downloads