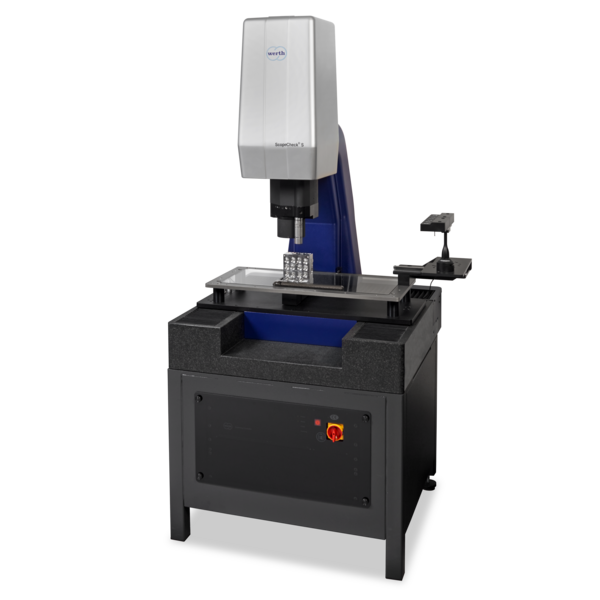

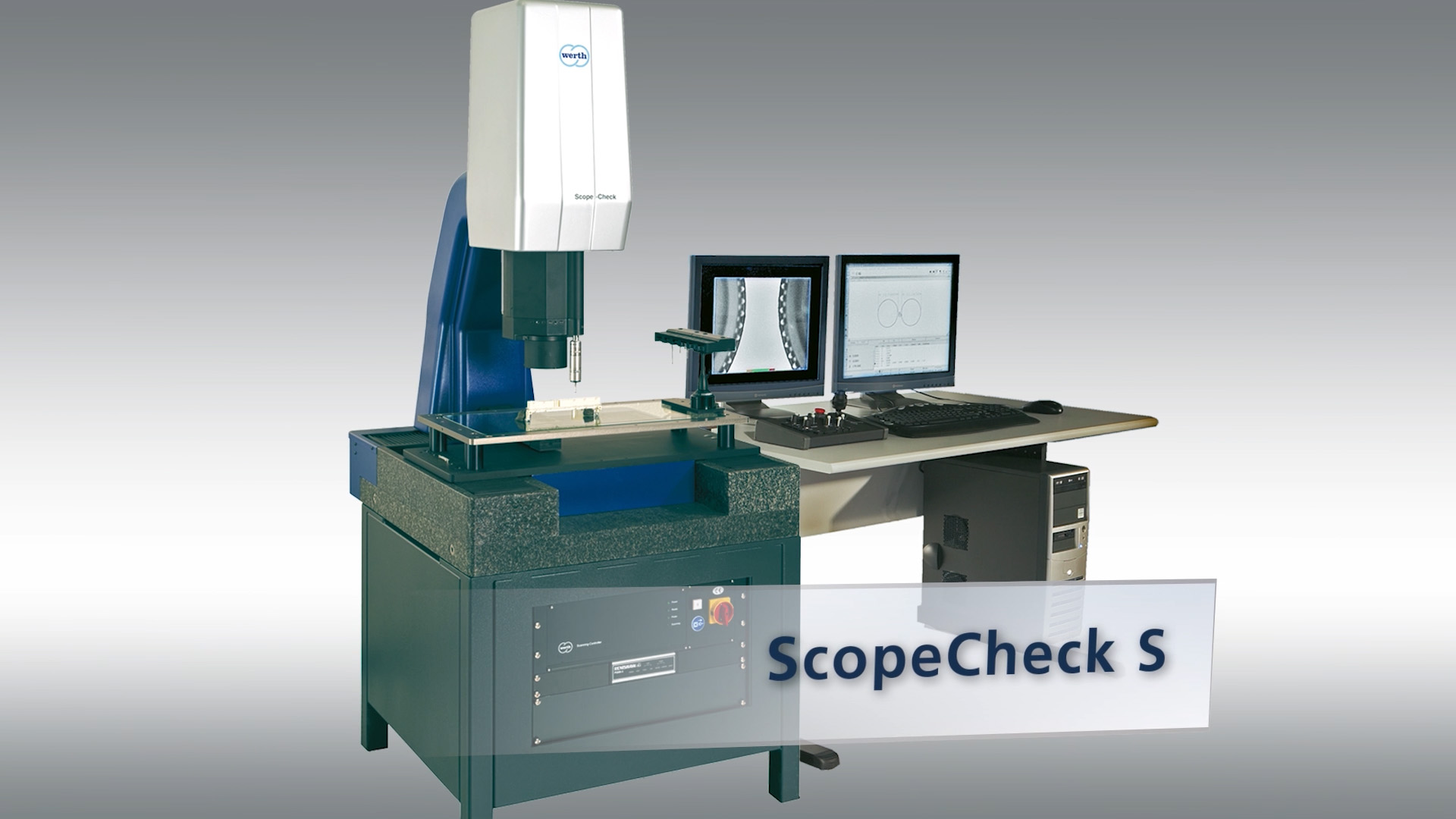

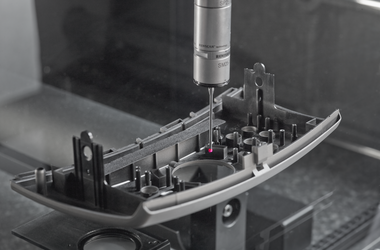

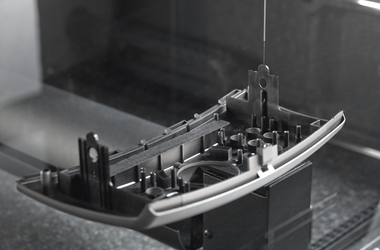

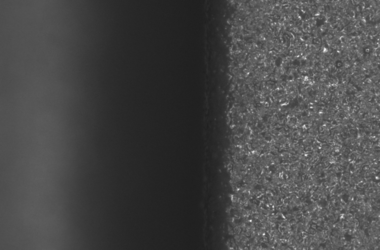

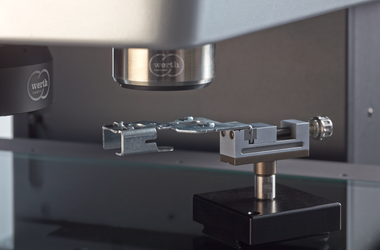

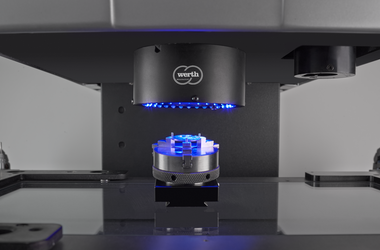

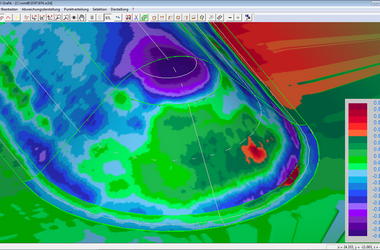

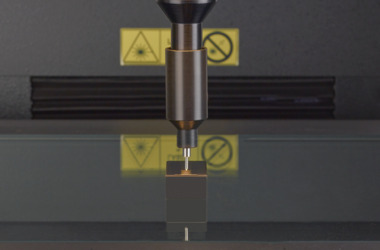

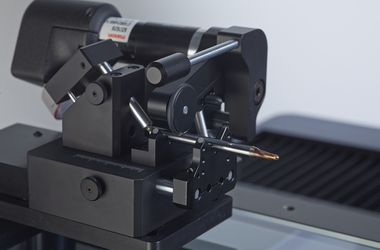

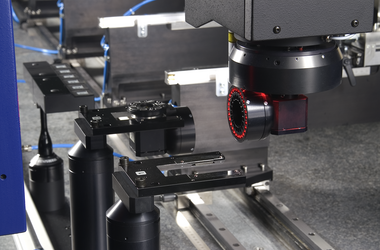

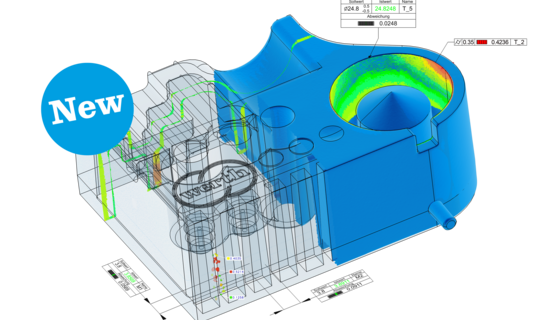

The compact ScopeCheck® S features an extremely robust granite and polymer concrete construction with protected guideways and scales, as well as temperature compensation, making it optimised for use in production environments. The Werth image processing sensor included in the basic equipment is specially tailored to the needs of dimensional metrology and provides reliable edge detection even in the most difficult contrast conditions. Different focus variation methods enable optical 3D measurements. Typical areas of application are turned, milled, plastic, punched and bent parts.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

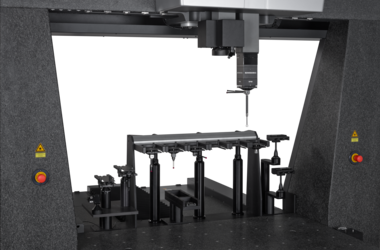

- Prismatic workpieces

- Stamped and bent parts

- Packaging

- Shaft-hub connections

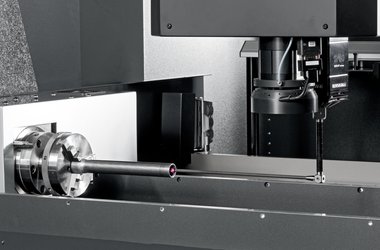

- Shafts and axles

- Workpieces with micro-features

- Workpieces with optical functional surfaces

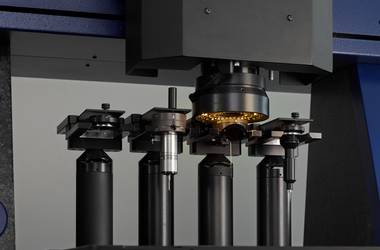

- Tools with geometrically defined cutting edges

- Tools with geometrically undefined cutting edges

- Gears

- Cylindrical workpieces

- Industries

- Products

- Service

- About Werth

- Careers

- Foundation

- Publications

- Downloads