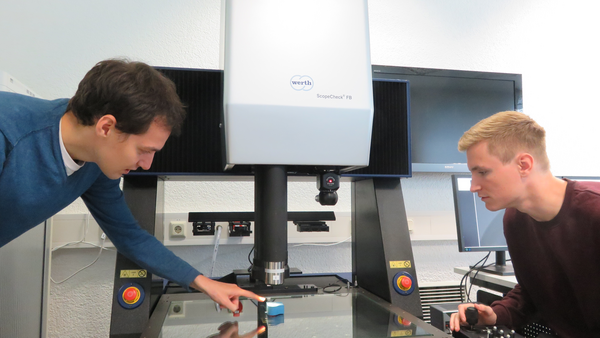

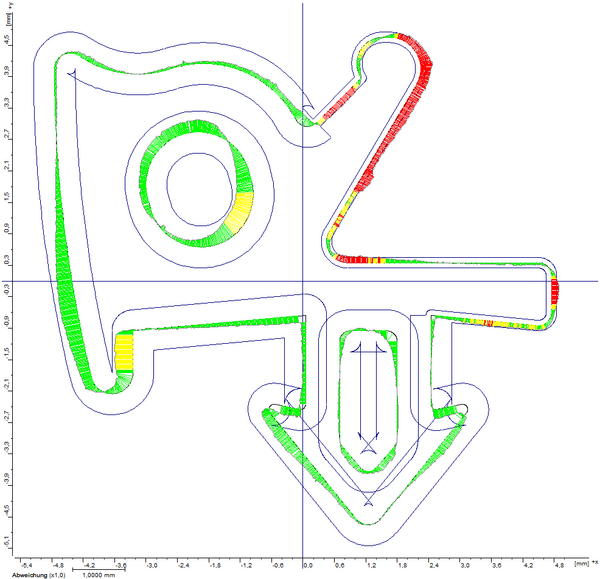

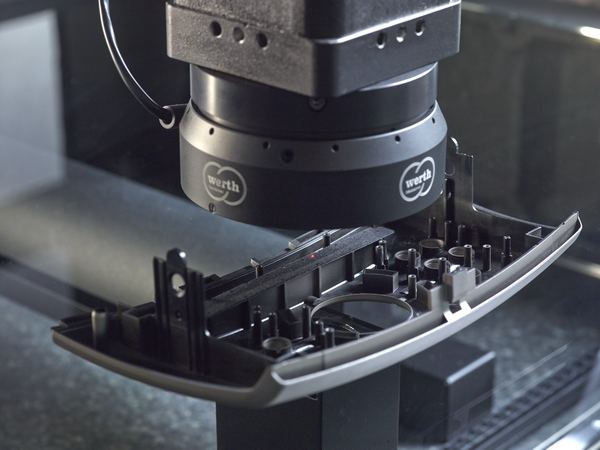

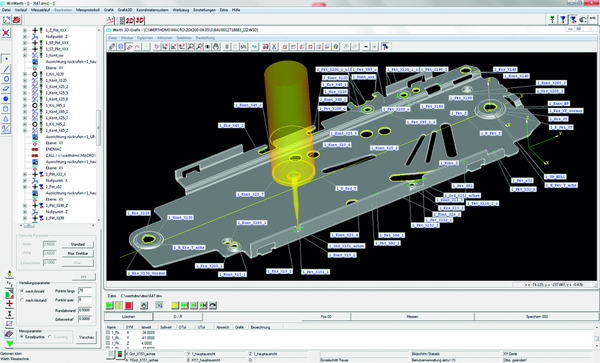

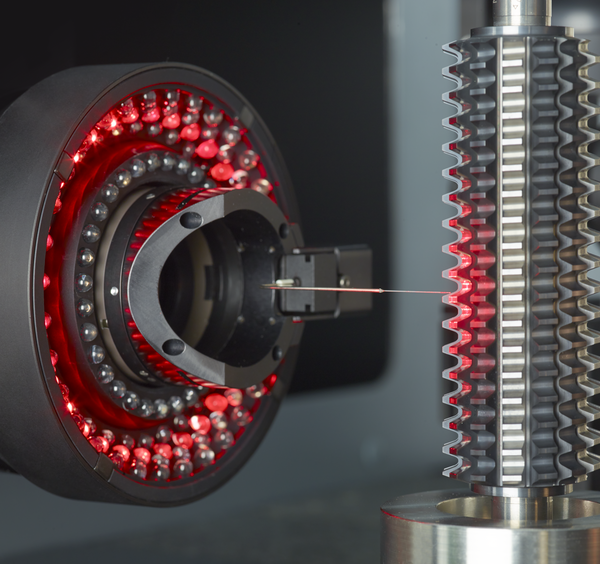

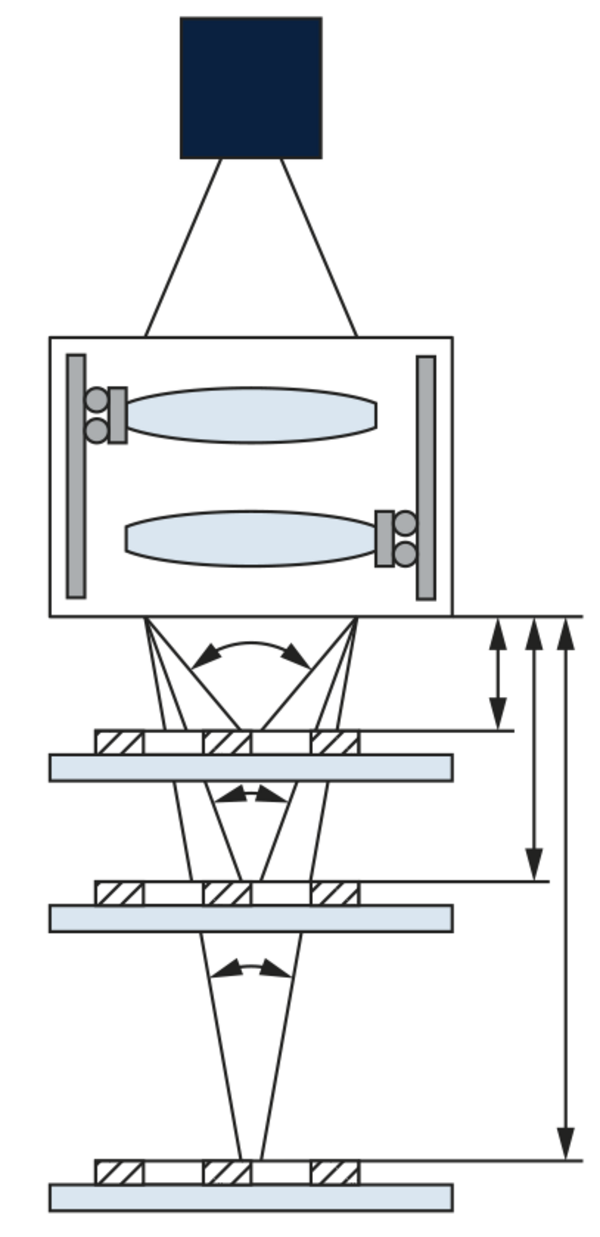

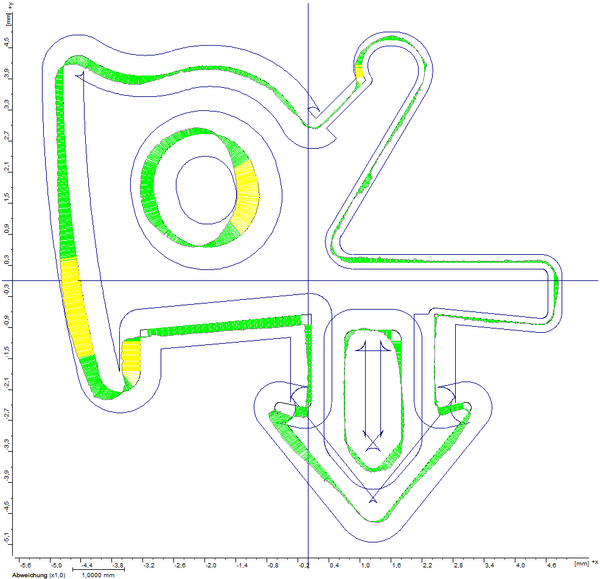

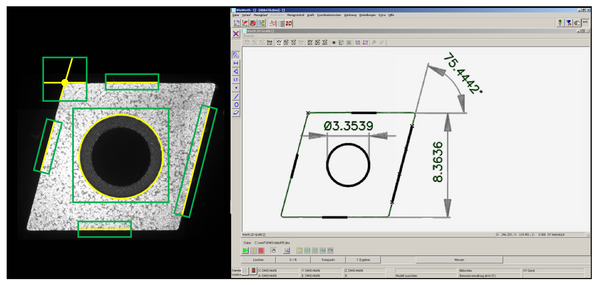

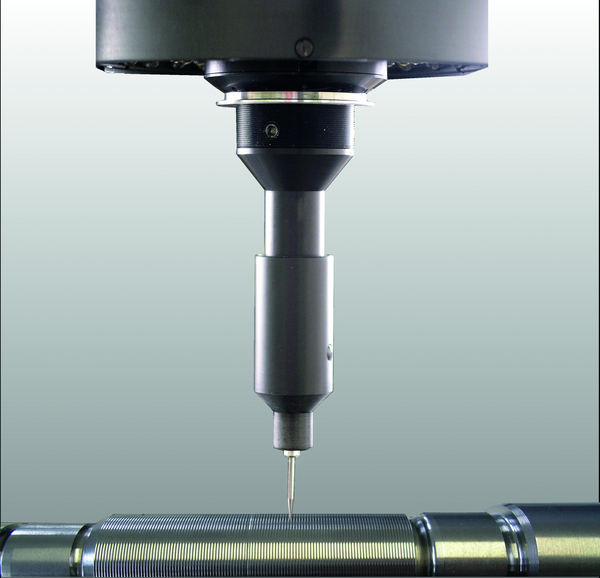

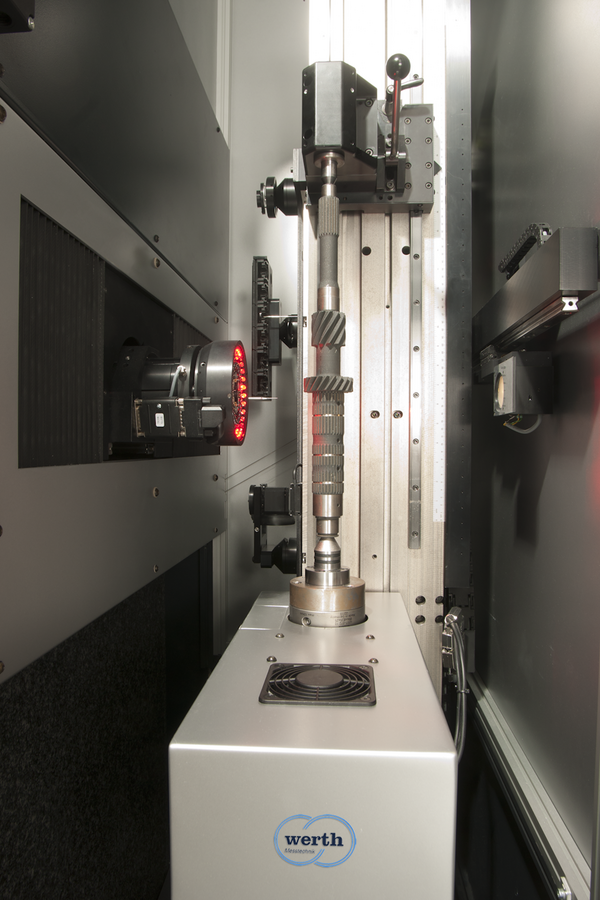

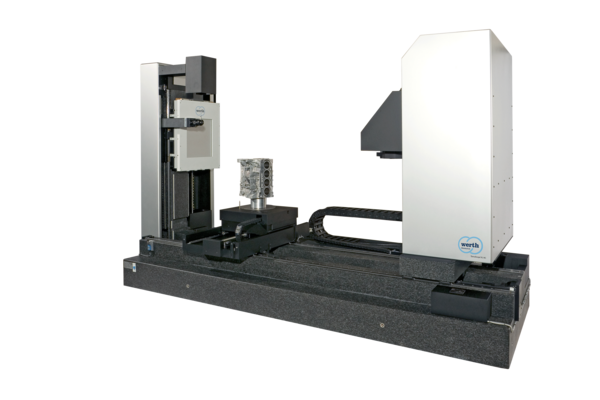

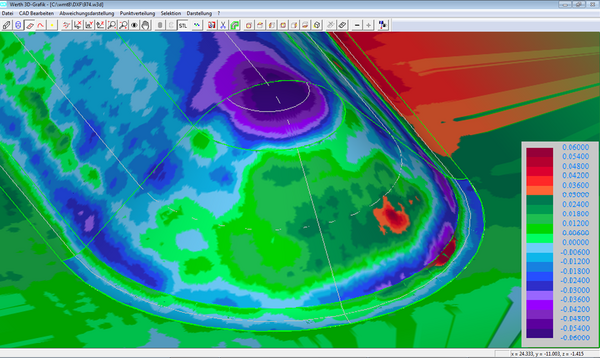

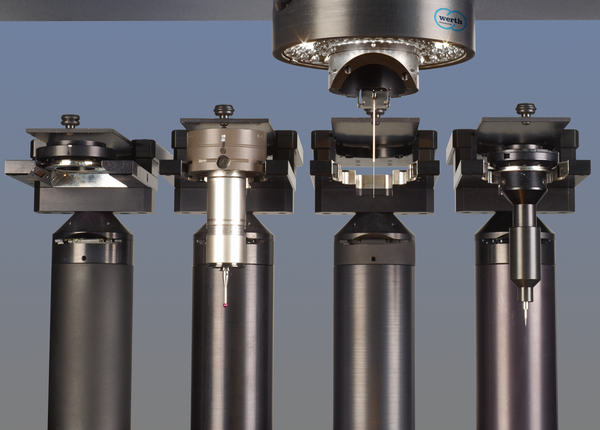

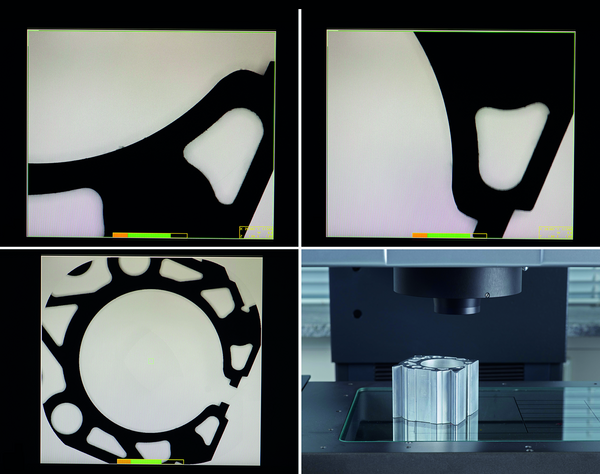

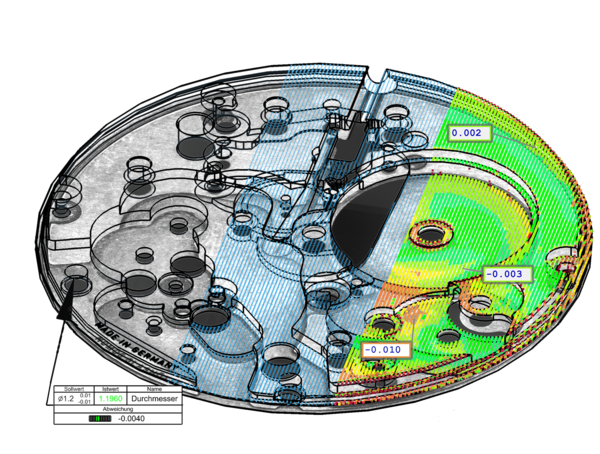

Coordinate measuring machines are used to measure geometrical characteristics of workpieces such as lengths, angles, diameters or even complex position tolerances. Machines with several sensors, e.g. image processing, laser and stylus, are called multi-sensor coordinate measuring machines.

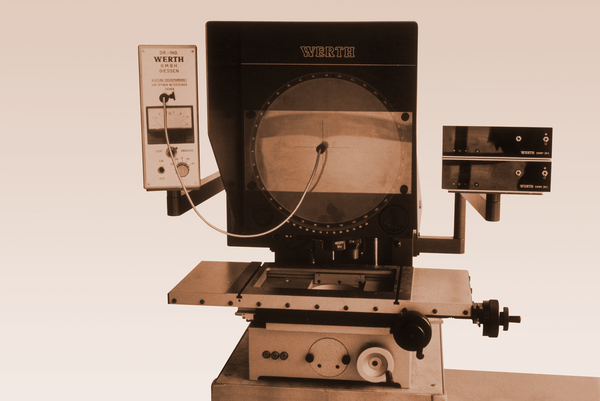

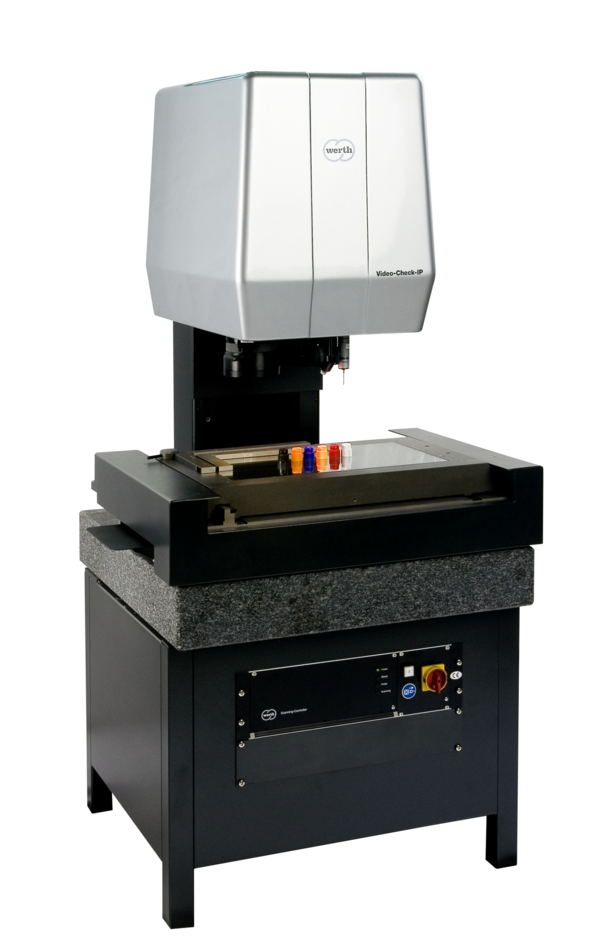

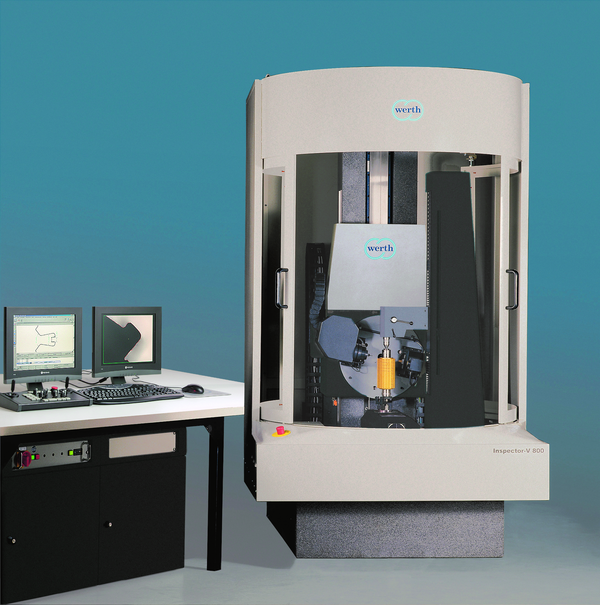

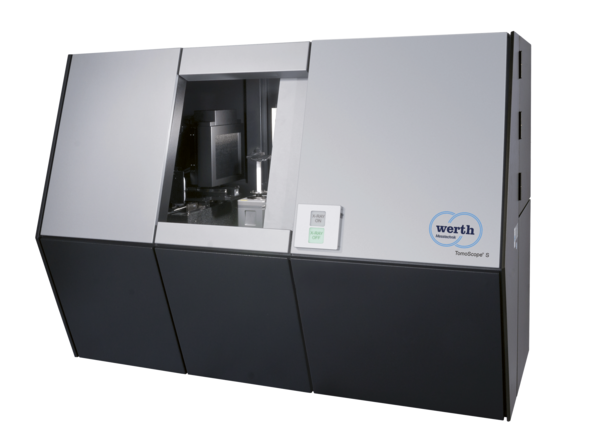

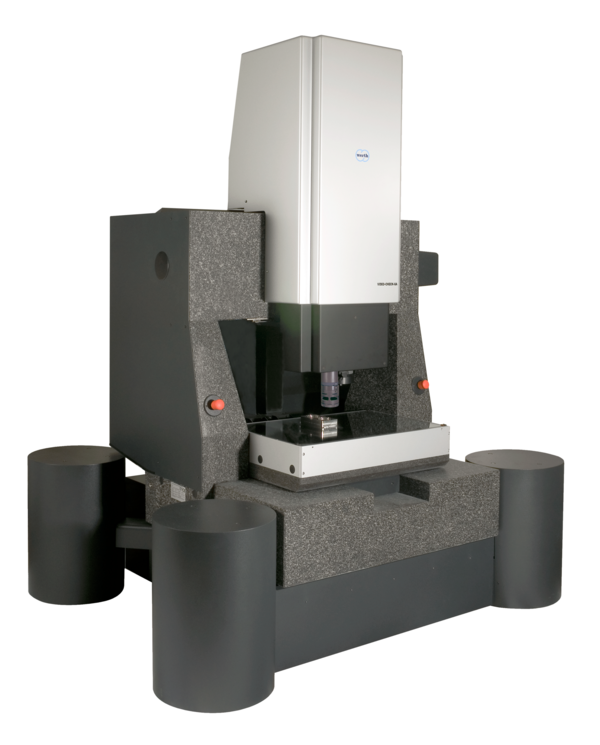

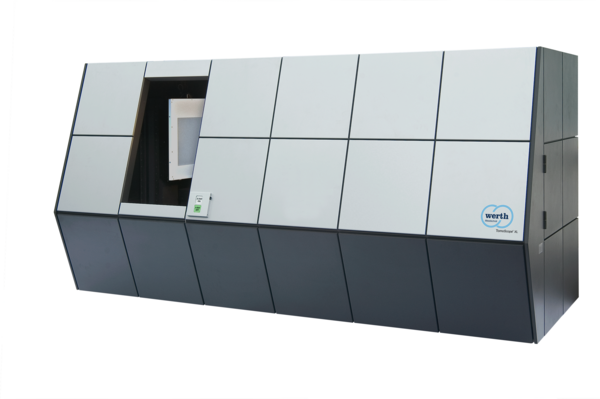

Werth concentrates on the development, manufacture and sale of coordinate measuring machines with optics, probe, computed tomography and multi-sensor systems as well as the measurement of micro-features. The company's global technology leadership in these market segments is reflected in a number of world firsts and patents on instrument technology and sensors. The achievable accuracy of Werth machines can be in the range of a few micrometres or, in the case of highly accurate systems, even in the range of a few 10 nanometres, making Werth the world leader in multi-sensor coordinate measuring machines.

Comprehensive services to support users in the application of the machines complement the field of activity and create a high level of customer satisfaction. The quality management system according to DIN EN ISO 9001 and the DAkkS laboratory for the calibration of coordinate measuring machines according to DIN ISO 17025 guarantee the reliability and accuracy of the machines. In 2003, Werth pioneered the development of accreditation procedures for laboratories with multi-sensor coordinate measuring machines together with the PTB. In July 2013, the DAkkS laboratory of Werth Messtechnik GmbH was also the first facility of its kind to be accredited for the calibration of coordinate measuring machines with X-ray tomography sensors.

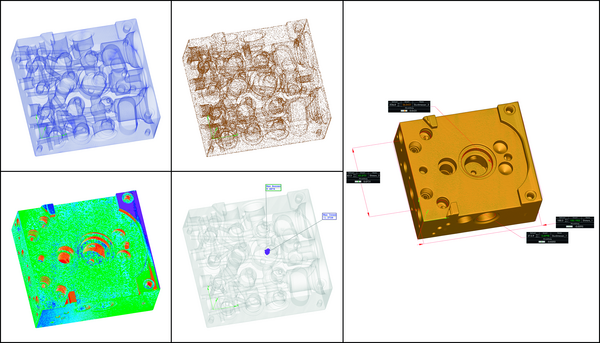

More than 10,000 Werth coordinate measuring machines are installed worldwide in a wide variety of industries. Examples of application fields for these machines are: Aerospace industry, automotive industry, electronics industry, jewellery manufacturing, watch industry, tool making, plastic injection moulding, medical technology, turbine construction as well as aluminum and plastic extrusion.