Version 9.45 of the WinWerth® measurement software offers many new and improved functions, such as helical tomography to increase accuracy with minimal measurement errors in the 0.5 µm range. With multi-spectral tomography, high-resolution, low-artefact measurements of workpieces and assemblies that are difficult to scan tomographically are possible in better quality. The new WinWerth® Viewer allows the automatic processing of existing projects and the additional manual evaluation and output of measurement reports with the usual WinWerth® range of functions.

Various smart functions have been added to the measurement software. The contours of several workpieces measured in one image can now also be automatically separated during measurements with the image processing sensor. Another new feature is the subsequent filtering of recorded 3D measured data, taking into account the process parameters of the sensors, which can significantly reduce probing errors when using multi-point sensors, for example. With WinWerth® user management, user rights can be restricted to the selection of a workpiece, even for the automatic start of the measurement programme. Once the measurement is complete, the machine is automatically logged out again by the logged-in user. Individual users can be managed directly via the Windows ActiveDirectory by linking them to Windows user accounts. For an improved overview, only features above the insertion point are displayed in the 3D graphic. The graphic can now be saved directly in the Office log.

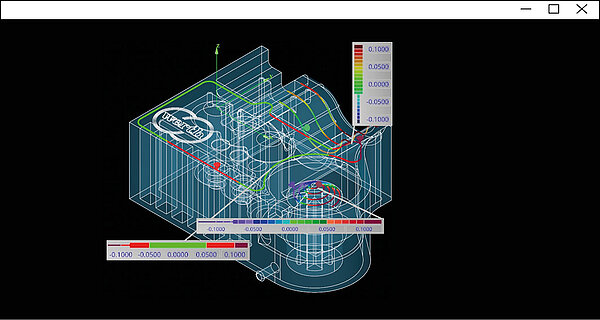

Different tolerance bands and individual colour scales can be set in WinWerth® 945

The modernised WinWerth® 9.45 user interface with clear lines and uniform, simplified dialogues increases ease of use. For form errors with different tolerances, the type of deviation display is now adjustable by the user within wide limits. The colour distribution diagram makes it easy to assess the size of systematic and random deviations.

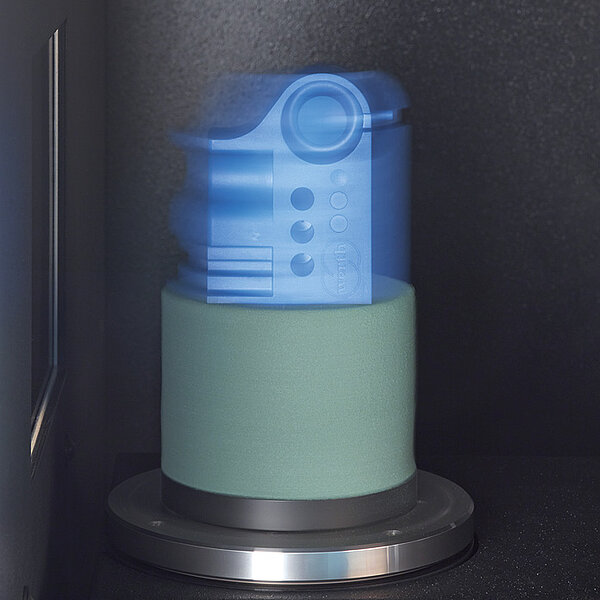

The range of functions has also been expanded in the area of computed tomography. OnTheFly CT (patent pending) to increase measuring speed is now available for all special measuring methods, including the patented Multi-ROI CT, for example. During offline programming with TomoSim, the quality of the simulated volume corresponds to the later measurement in terms of resolution, artefacts and many other properties. The simulated intensity image can be used to optimise the tube power and position of the workpiece on the detector.