Fuel cell stacks made of bipolar plates, such as those used for motor vehicles, enable vehicles to operate without emitting exhaust gases. Two half plates (anode and cathode) are joined together to form a bipolar plate. These serve on the one hand to supply gas or liquid, and on the other hand as electrodes with the aid of which electricity is generated from the oxidation of hydrogen by chemical reaction.

The ScopeCheck® FB is suitable for measuring the plates. These and the associated embossing tools are measured, for example, at a renowned automotive supplier with a VideoCheck® HA (High Accuracy)..

Tools measurement

The production time for the embossing tools is about 80 hours. To avoid product rejects, 100 % inspection is required with tolerances between 3 μm and 10 μm. For this purpose, the Werth image processing sensor automatically scans the entire tool in the patented Raster Scanning HD mode. By superimposing many individual images taken during the movement, an overall image of the tool is created. All visible two-dimensional geometric properties can then be evaluated very quickly from this.

Since the wave profiles of the tools have the smallest radii of 0.1 mm, conventional probes are unsuitable for measurement. The patented Werth Fiber Probe WFP® 3D with glass stylus tips as small as 20 μm or the non-contact measuring Chromatic Focus Point CFP can be used for highly accurate and fast measurements. Area measurements are possible with the Chromatic Focus Line CFL. The line sensor allows the entire workpiece surface to be measured with 10 000 points/mm2. From this, surface profile deviation, line profile deviation, embossing depth, flank angle and pitch can be determined. After measuring the tool center offset, a virtual pairing of the upper and lower tool plates is possible.

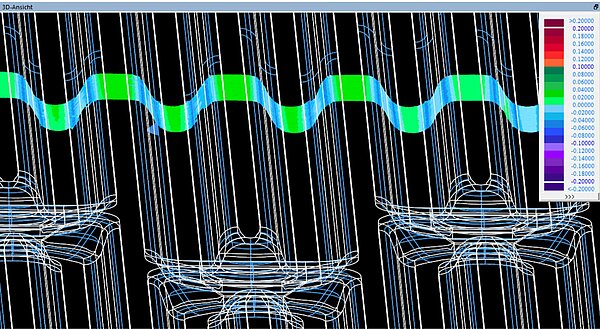

Color-coded deviation plot of the flowfield's surface profile shape