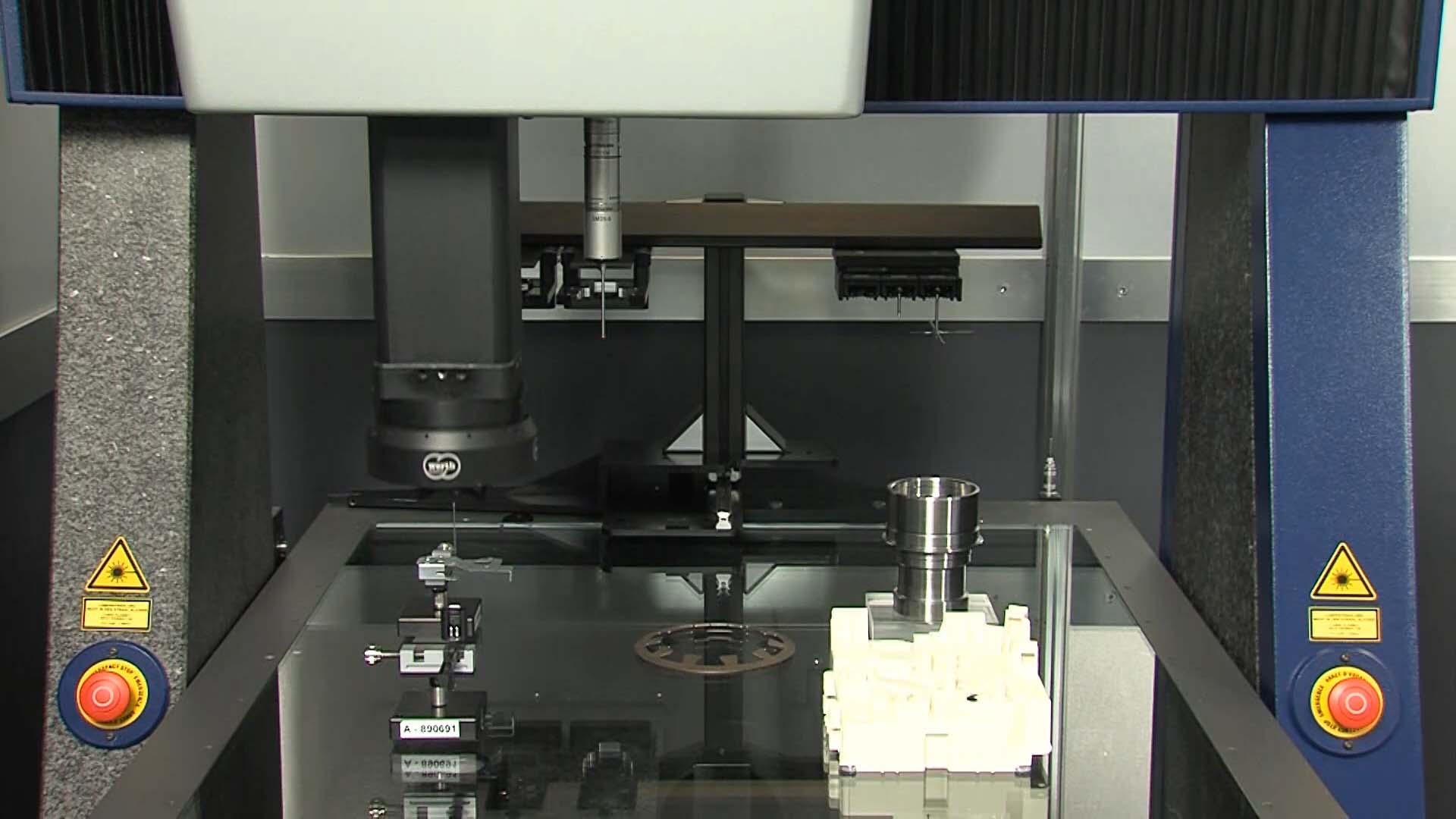

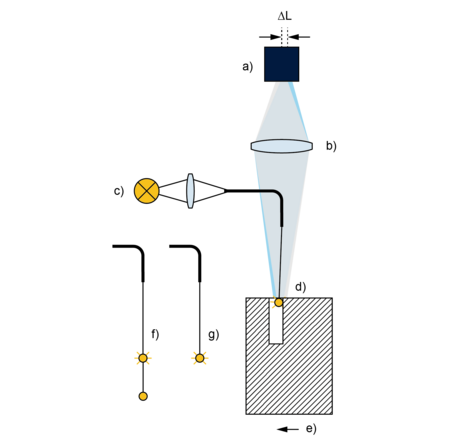

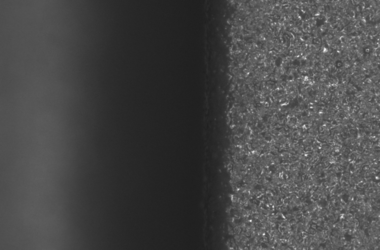

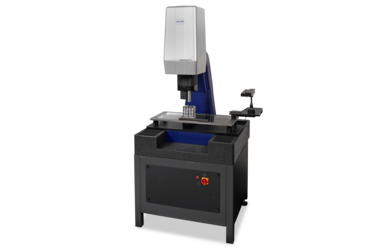

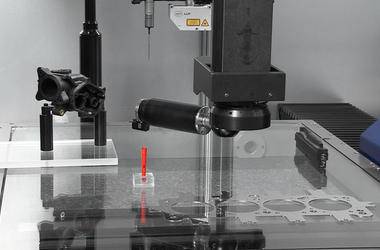

The patented Werth Fiber Probe® WFP 2D has set the industry standard for micro-probes for decades and enables highly accurate tactile measurements of extremely small geometries with the smallest probing forces. Due to its low probing forces, the WFP® is also suitable for calibrating optical measurements on workpieces with sensitive surfaces. Typical areas of application are rubber and plastic parts, gauges, spinnerets, micro-gears and micro-bores on injection nozzles and turbine blades.

-

Applications

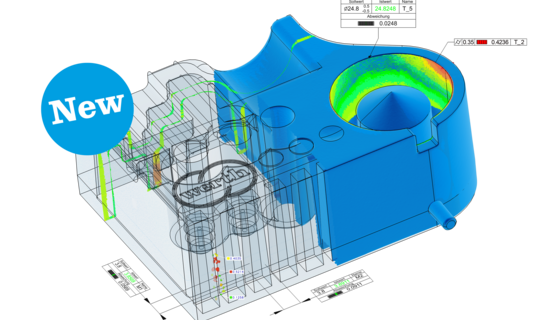

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

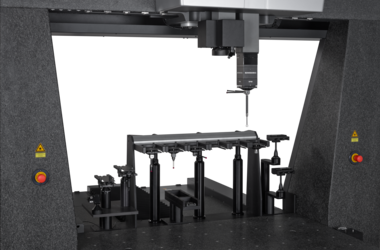

- Stamped and bent parts

- Packaging

- Shaft-hub connections

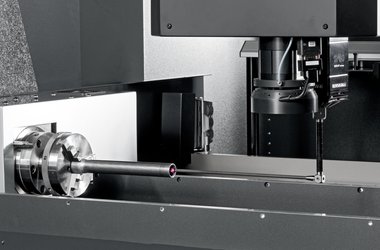

- Shafts and axles

- Workpieces with micro-features

- Workpieces with optical functional surfaces

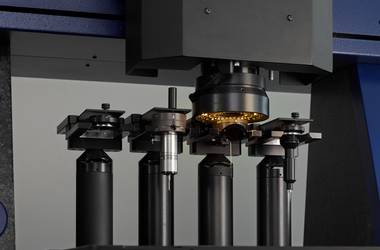

- Tools with geometrically defined cutting edges

- Tools with geometrically undefined cutting edges

- Gears

- Cylindrical workpieces

- Industries

- Products

- Service

- About Werth

- Careers

- Foundation

- Publications

- Downloads