The sub-microfocus tube increases the resolution of the two-tube measuring system by an order of magnitude, achieving a resolution of less than one micrometre. The 300 kV microfocus tube enables the measurement of large or dense workpieces with resolutions in the range of a few micrometres. This makes the machine suitable for applications with widely varying resolution requirements and for different workpiece sizes and materials. Almost all computed tomography measurement tasks can now be solved with a single machine. By combining it with region-of-interest computed tomography (ROI-CT), several small details can also be measured on comparatively large workpieces (patent). For this purpose, the overview CT is measured with the microfocus tube and the ROI with the submicrofocus tube at a higher magnification.

Powerful duo

The microfocus tube achieves voltages of up to 300 kV with a maximum power of 80 W and focal spot sizes of a few micrometres. The transmission target enables such small focal spot sizes even at maximum power. This means that large or dense workpieces can be measured quickly and with high resolution.

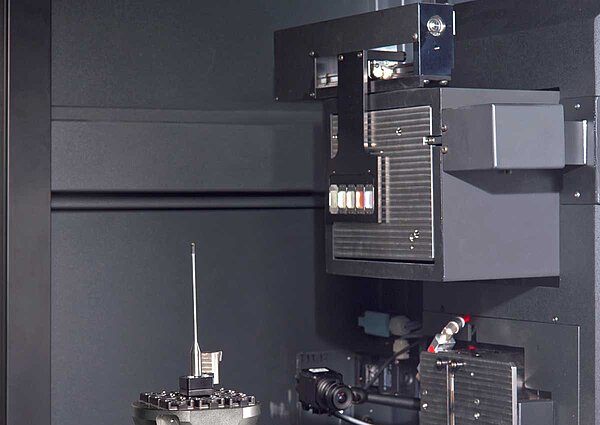

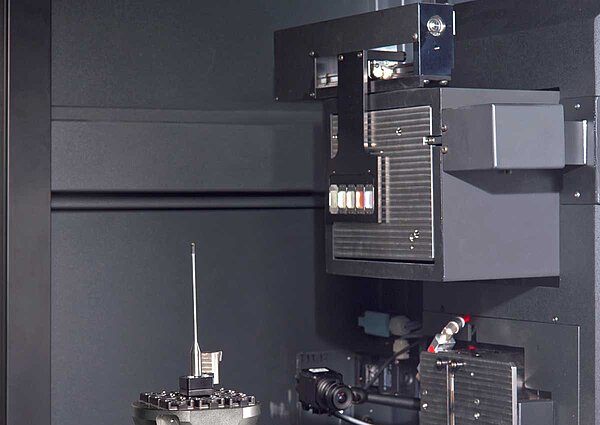

Two-tube measuring system: micro-focus tube (top) and sub-microfocus tube (bottom)

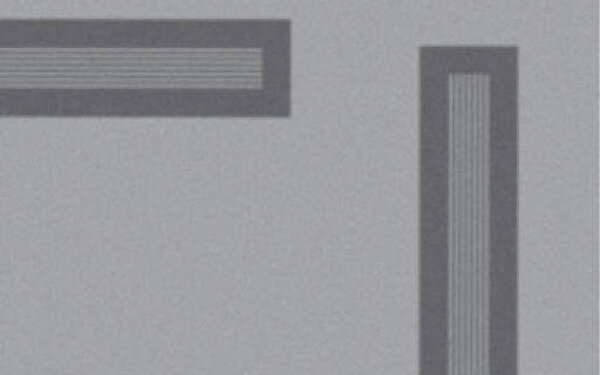

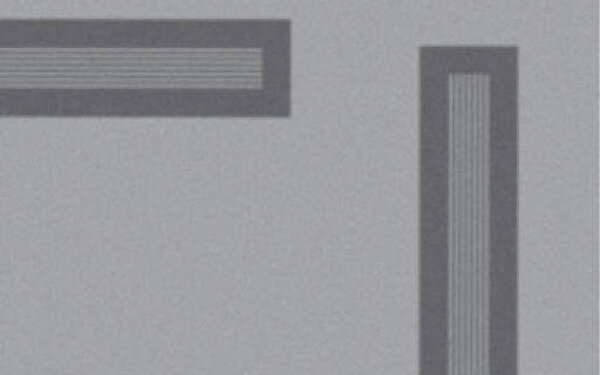

The sub-microfocus tube has a maximum voltage of 160 kV and up to 50 W power. Thanks to an additional focussing unit, it achieves a small focal spot size of 0.5 μm. The characteristic of a CT machine is often specified as the resolution in the radiographic image, which usually does not correspond to the resolution in the volume, or only a voxel size is specified, which can be chosen to be almost arbitrarily small. Neither of these is a measurement of the structure size that is actually resolved. With the Werth sub-microfocus tube, the resolution in the radiographic image is 0.5 μm.

Radiographic image of a structure standard with a line width of 0.5 μm: The structure is resolved

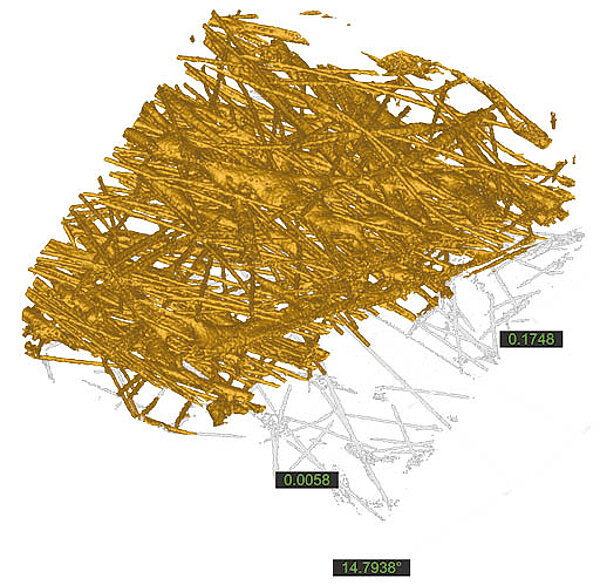

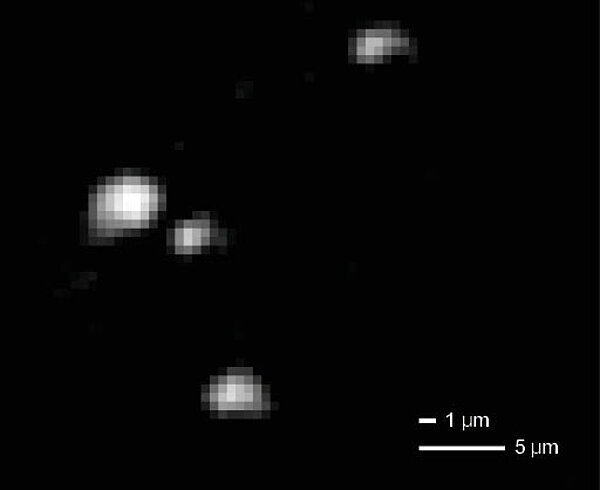

The effective resolution of a CT coordinate measuring machine results mainly from the combined effect (convolution) of the resolution functions of the focal spot, rotary axis and detector, taking the magnification into account. For this reason, the machine is also equipped with a highly accurate rotary axis with radial run-out errors of less than 0.2 μm. This means that the practical volume structure resolution of the two-tube measuring system with sub-microfocus tube is approx. 1 μm. Applications of the sub-microfocus tube include measurements of the fibre structure of filter materials, the measurement of the penetration depth of particles with colour-coded display and the measurement of particle sizes.