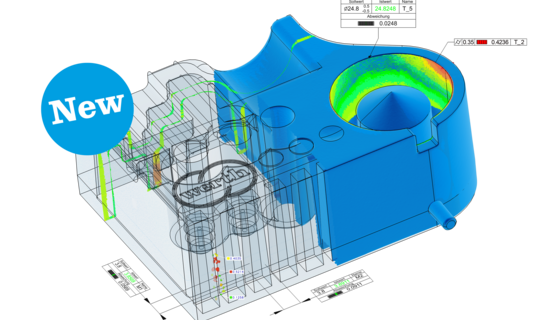

无论是单个工件还是完整的组件,无论是金属、塑料还是陶瓷,由于灵活的... 了解更多

- 联系我们

- 注册

-

Deutsch

- Deutsch (Deutschland)

- Deutsch (Österreich)

- Deutsch (Schweiz)

- English (International)

- English (USA)

- Link to Werth Metrology UK

- Français

- Link to Werth France

- Français (Suisse)

- Italiano

- Italiano (Svizzera)

- Español

- Português (Portugal)

- Português (Brasil)

- 中国

- Nederlands

- Polski

- Česky

- Link to Werth Magyarorszag HU