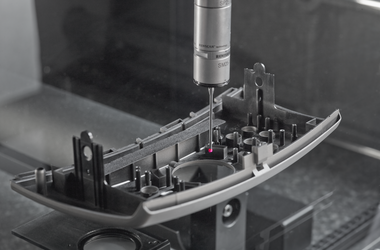

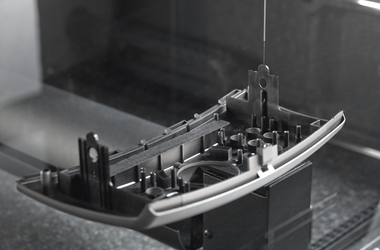

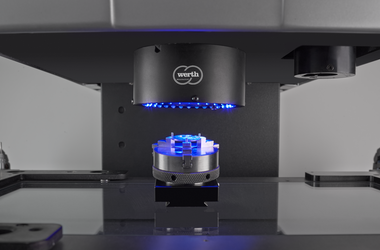

In medical technology, the individualisation of implants up to batch size 1 is increasing. New manufacturing processes enable more complex, sometimes very small structures. This poses new challenges for production and metrology.

The bone plates must be measured economically with high resolution and short measurement times.

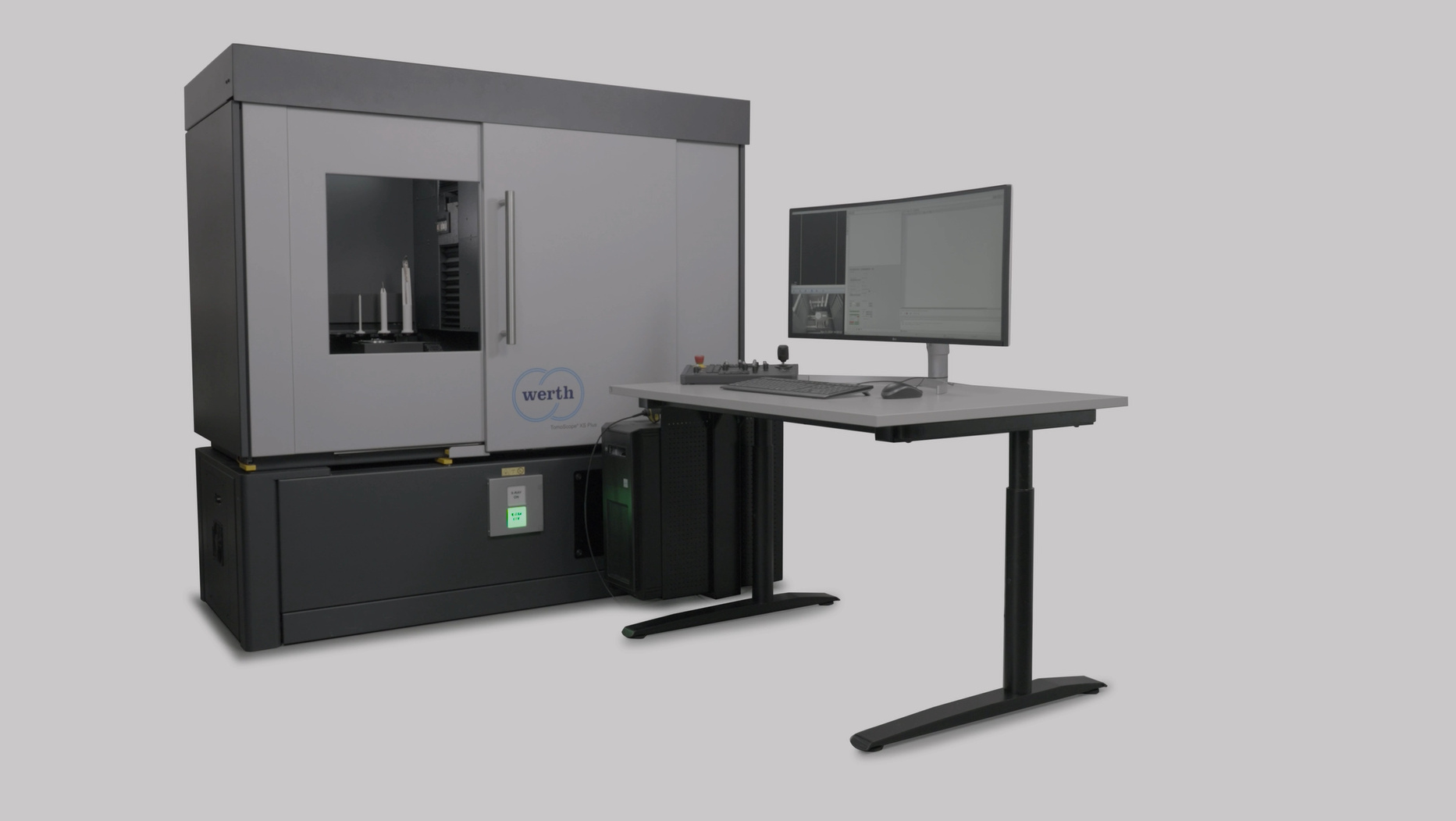

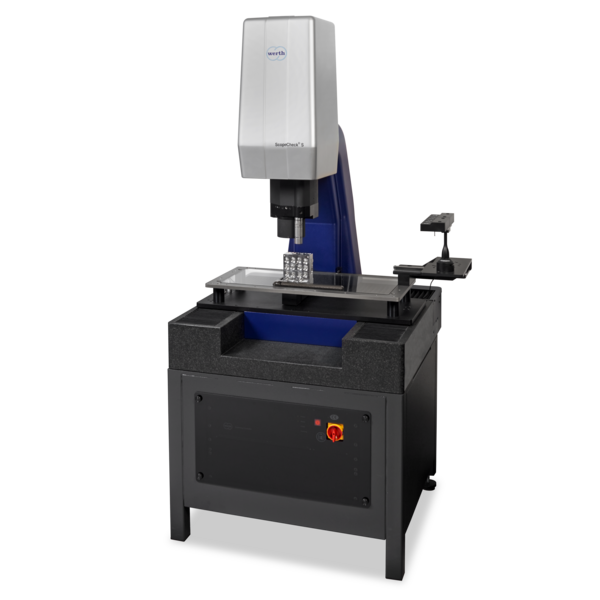

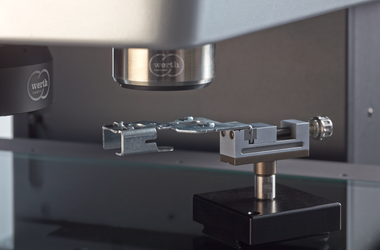

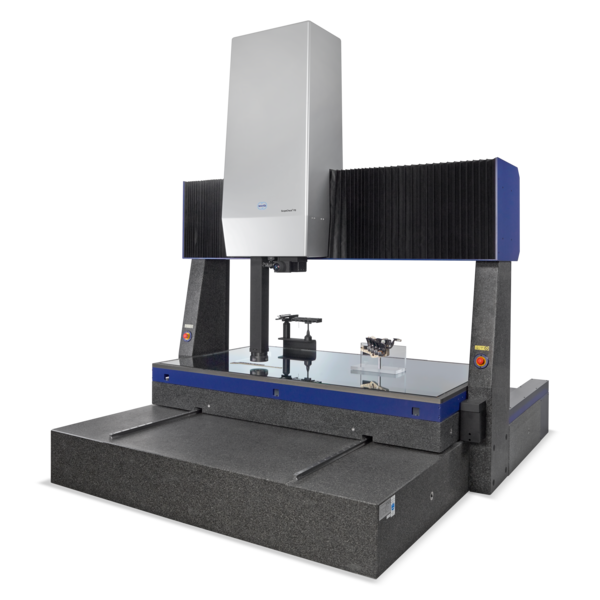

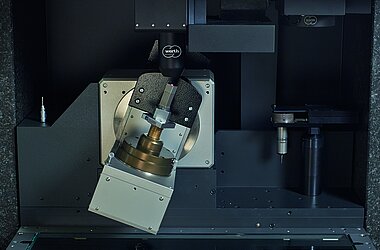

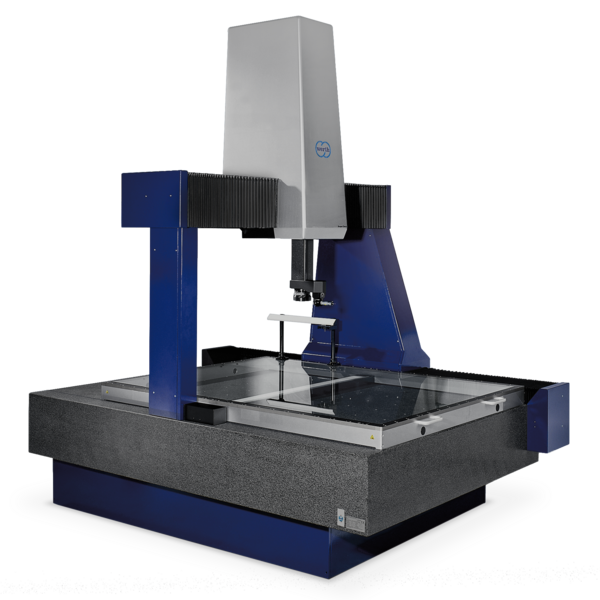

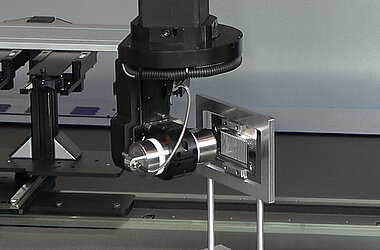

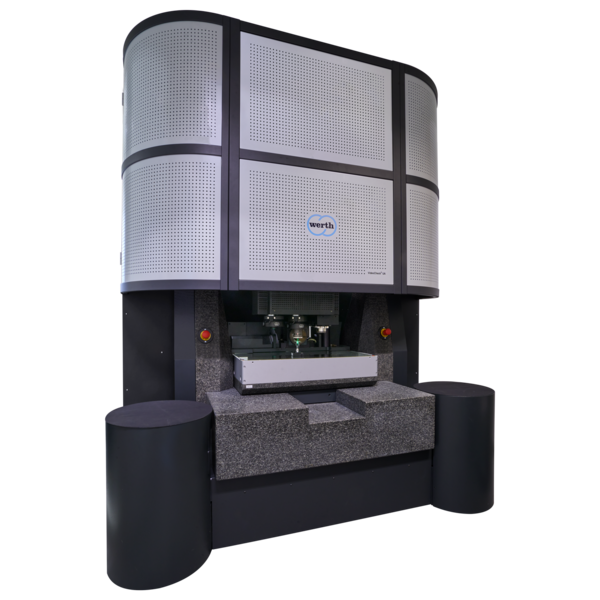

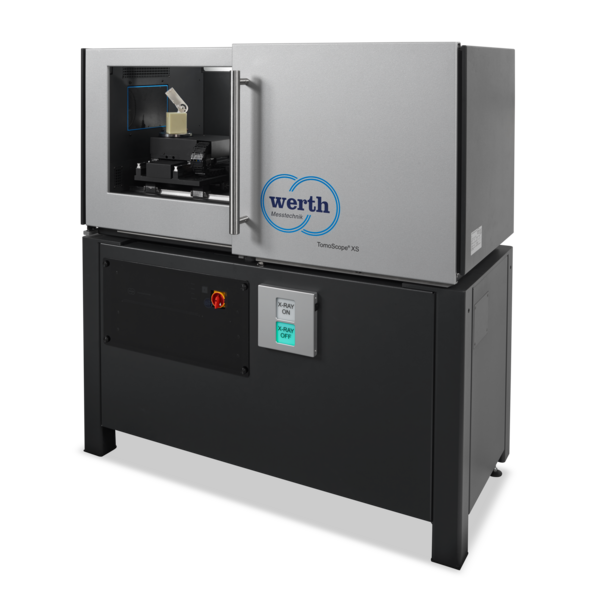

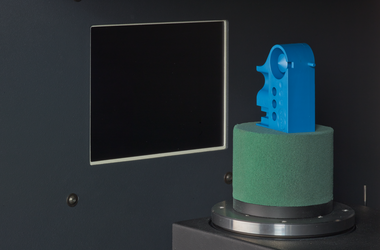

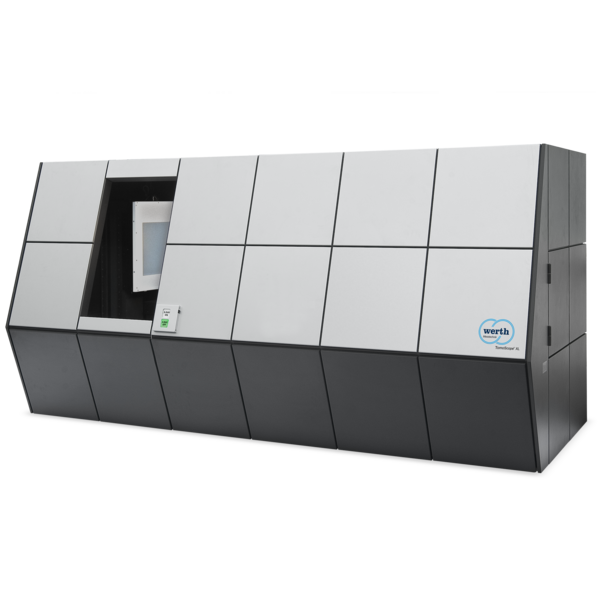

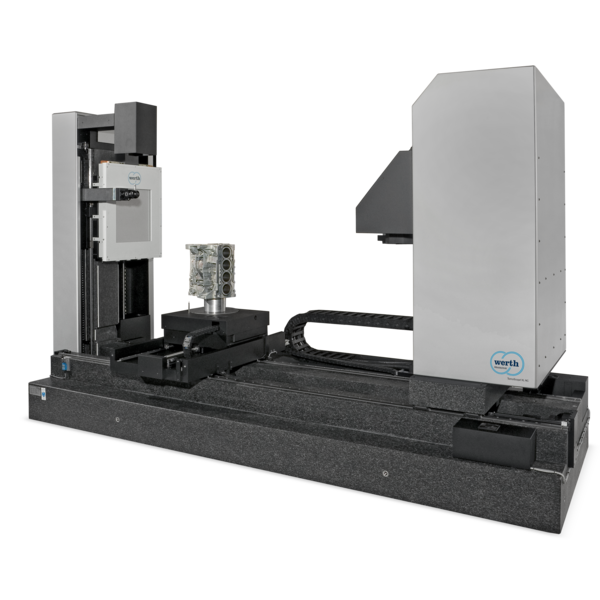

With the Werth TomoScope® XS machines and the Werth Longlife transmission sources used, threads and wall thicknesses on bone plates or the Torx drive of a screw can be measured reliably and quickly.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Stamped and bent parts

- Packaging

- Shaft-hub connections

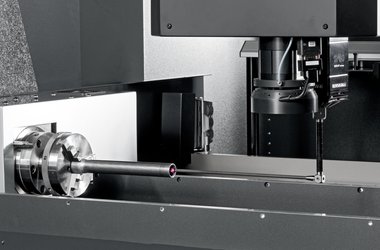

- Shafts and axles

- Workpieces with micro-features

- Workpieces with optical functional surfaces

- Tools with geometrically defined cutting edges

- Tools with geometrically undefined cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Products

- Service

- About Werth

- Careers

- Foundation

- Publications

- Downloads