-

Applications

- 3D free-form workpieces

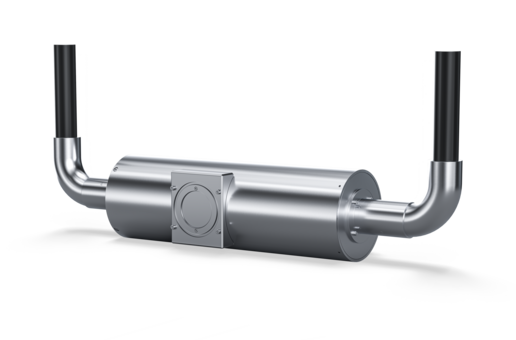

- Extruded workpieces

- Moulds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Stamped and bent parts

- Packaging

- Shaft-hub connections

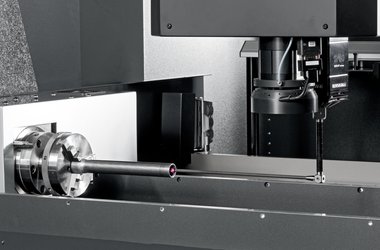

- Shafts and axles

- Workpieces with micro-features

- Workpieces with optical functional surfaces

- Tools with geometrically defined cutting edges

- Tools with geometrically undefined cutting edges

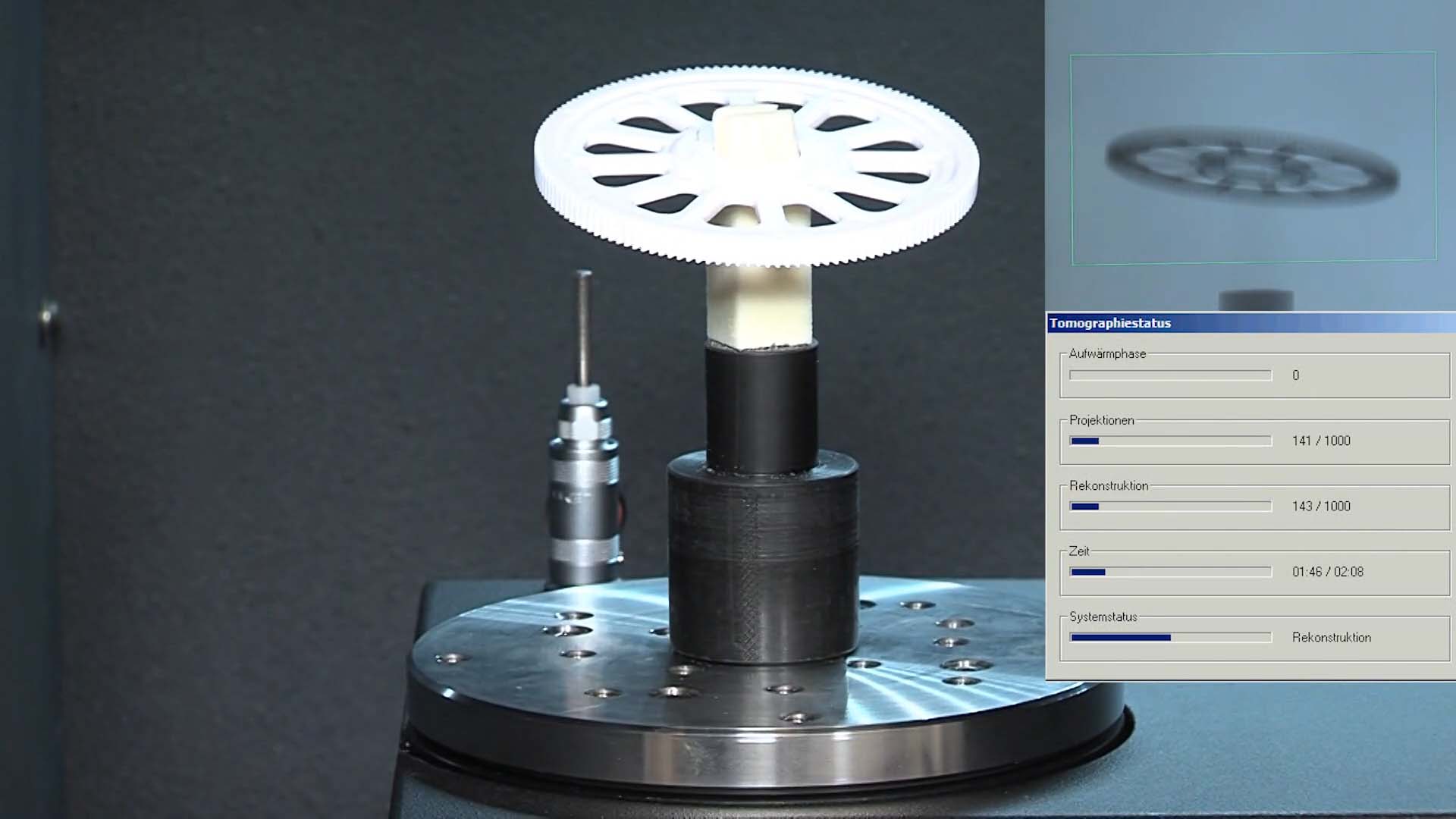

- Gears

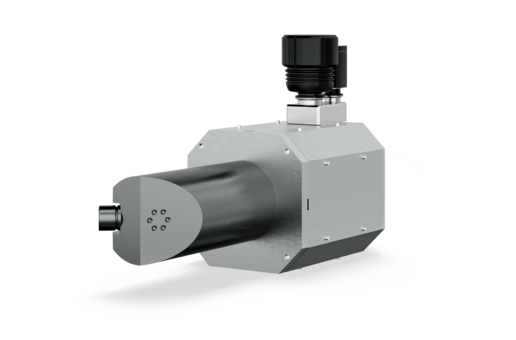

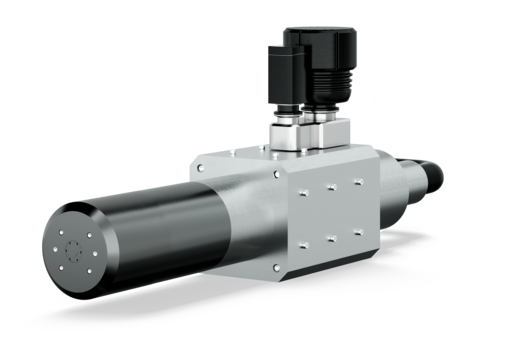

- Cylindrical workpieces

- Industries

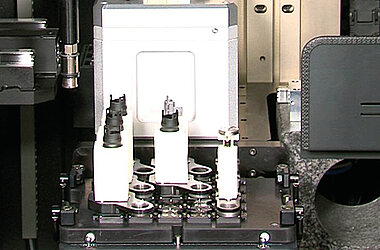

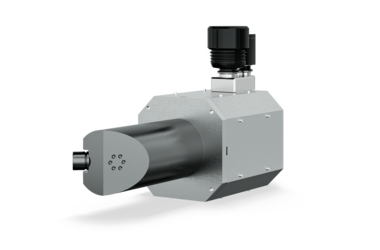

- Products

- Service

- About Werth

- Careers

- Foundation

- Publications

- Downloads

- Contact

- Login

-

Deutsch

- Deutsch (Deutschland)

- Deutsch (Österreich)

- Deutsch (Schweiz)

- English (International)

- English (USA)

- Link to Werth Metrology UK

- Français

- Link to Werth France

- Français (Suisse)

- Italiano

- Italiano (Svizzera)

- Español

- Português (Portugal)

- Português (Brasil)

- 中国

- Nederlands

- Polski

- Česky

- Link to Werth Magyarorszag HU