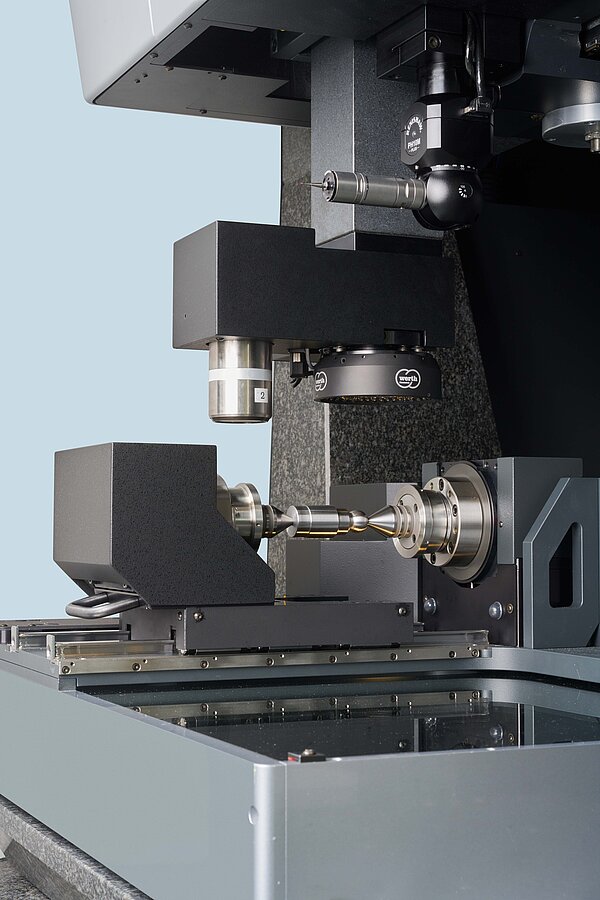

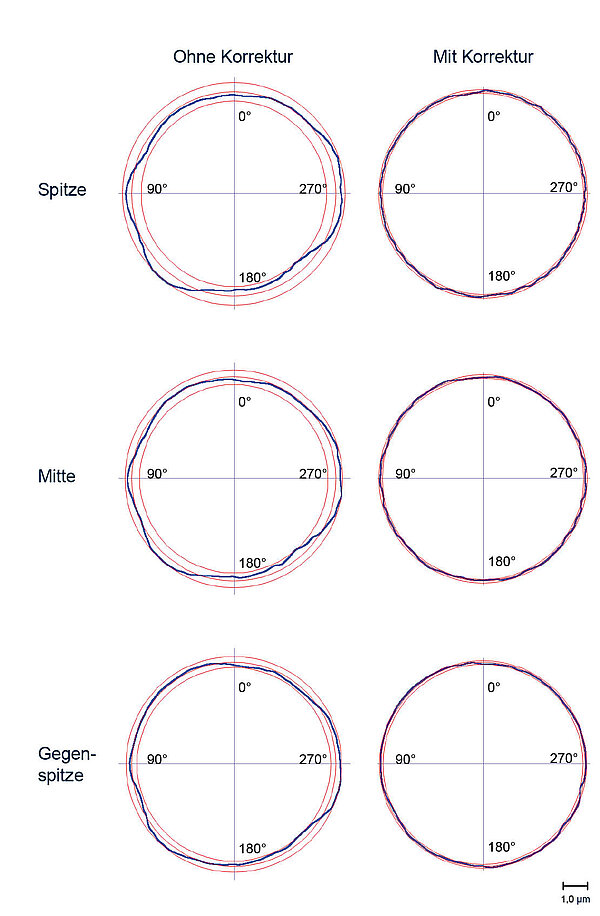

The new rotary axis with air-bearing tailstock enables the smallest measurement errors over the entire length of the workpiece (e.g., 350 mm)

A new rotary axis solution in combination with the corresponding software now makes it possible to measure roundness and straightness on the coordinate measuring machine with previously unattained accuracy. In particular, the patented Rasterscanning HD operating mode and the new RotaryScan HD are used here. Thanks to a high-precision telecentric lens, a rotary axis with air bearings and a new correction method, minimal measurement errors in the range of 200 nm are achieved for the reliable detection of roundness tolerances down to 2 μm.